Let Precision Badges manufacture your next consignment of custom lapel pins, names badges or key rings for your school or business.

The founding directors of Precision Badges NZ have been in the badgemaking business for over 50 years, and Precision Badges was incorporated in NZ in 1997. We're proud suppliers of quality badges and medals to schools, clubs and businesses across New Zealand. We aim to supply schools and businesses with the best quality metal and embroidered badges, keyrings, and plaques at the most competitive prices available. In most cases there are no setup, artwork or tooling charges.

We carry the largest variety of school or club title bars available throughout New Zealand and can usually have your custom designed order delivered to your door within 2 to 3 weeks of your order confirmation.

Online ordering of title bars is now available.

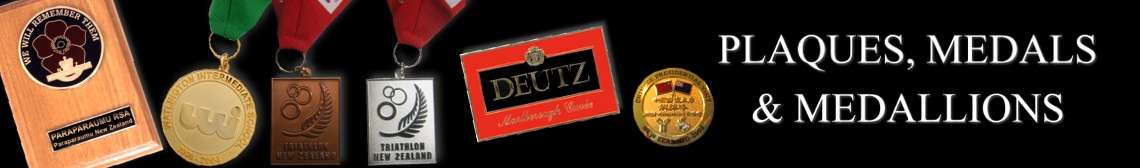

We make it easy for you and have the latest manufacturing technologies that enable us to produce the widest variety of quality badge types on the market today. Anything from tie pins to the biggest of plaques, in any shape or colour, Precision Badges is the New Zealand owned and operated company to trust when you want quality product and friendly, helpful service. Give us a call and we'll discuss the options available to best promote your business name, or help you design your new club, school or corporate badge.

Please download and view our 2024 school lapel pin and name badge brochure (14.5 MB PDF file) and browse the print catalogue to see for yourself the quality, workmanship and capabilities of Precision Badges. We can help you with your next project whether it be something totally new for your organisation, or just a simple re manufacture of your existing badges or medals.

Precision Badges have the latest manufacturing technologies enabling us to produce the widest variety of quality badge types on the market today. We're an independently owned and operated NZ company that you can trust. We've complied a list of frequently asked questions relating to getting your own badges made.

Precision Badges have the latest manufacturing technologies enabling us to produce the widest variety of quality badge types on the market today. We're an independently owned and operated NZ company that you can trust. We've complied a list of frequently asked questions relating to getting your own badges made.